Lets cut through the structural repair jargon

Do the terms ‘remedial lateral restraint’, ‘floor/wall strapping’, or ‘crack stitching’, mean much to homeowners, or house buyers? Probably not. It’s technical jargon, alluding to methods of fixing bulging walls and cracks – in plaster, walls, or ceilings.

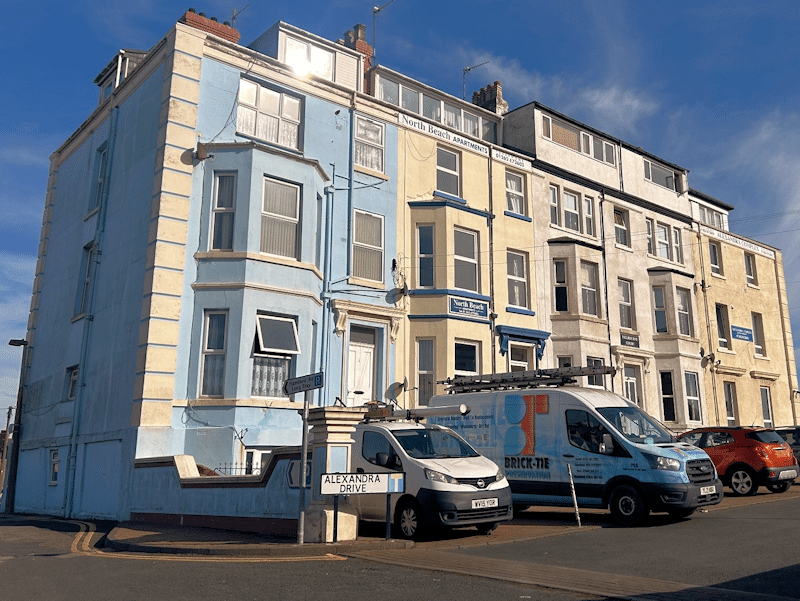

This article is only slightly technical, let’s cut the jargon and try to break down barriers, so you can understand how we help customers fix their buildings. I recently used these methods to save an apartment block in Bridlington, which was in dire need of repair, so that it could be refurbished and re-occupied. I’ll use this example to explain what the jargon means, and show how even the worst crumbling building like this one, can be fixed by Brick-Tie. This post should be useful for you, especially if you are navigating a structural report or quotation for structural repairs. Noticed cracking or bulging, give me a call. Please don’t rely on this post to make any diagnosis yourself. These things are not overly complicated, but do require an experienced eye to get right. Every building is unique in one way or another, call our team at Brick-Tie if you need a survey.

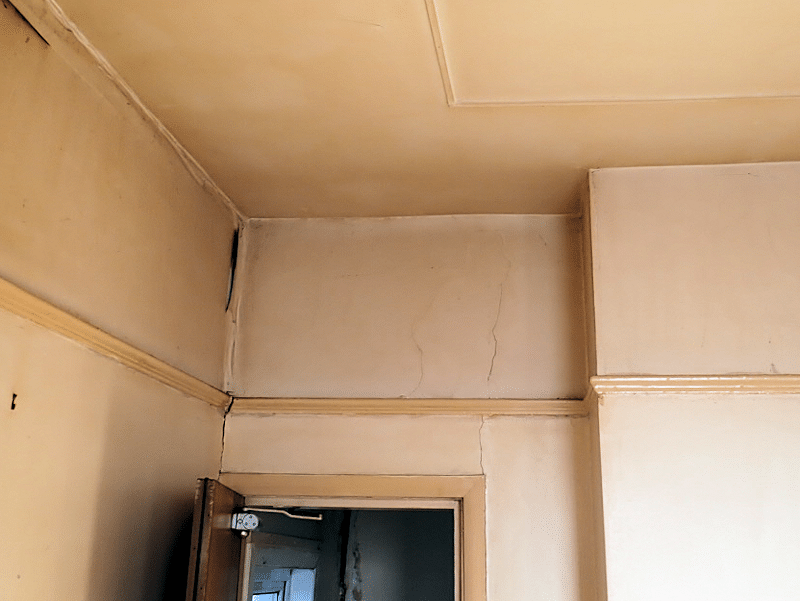

I’ve included captioned images to show how quite serious structural movement can be difficult to spot, and what the results of botched repairs, or delayed intervention can lead to. If you are interested please read the copy below, but if you just want the gist of things, the photos and captions should do.

The long and slow progress of a house falling apart

This structural problem started over 50 years ago, but only sprung to life when a bulge became obvious. As you’ll see, previous owners had discovered the cracks inside the upper rooms. They innocently filled them, and decorated many times over the years. With no specialist advice they didn’t realise that filling the cracks would not help – it was becoming much worse.

The bulge is obvious at ground floor level, but the wall is four stories high. From the path the upper parts look straight. As Brick-Tie technical director, I was tasked with investigating cause, and designing a repair. Brick-Tie were introduced to the owner via recommendation, from two separate independent structural engineers he’d contacted about the bulge.

Our client had vacant possession of all the upper floor flats, and the furniture had been removed before I arrived. The low level bulge couldn’t be missed. When I surveyed the interior it was obvious to me, that here was a classic case of in-built lack of lateral restraint. Briefly this means that the high gable, with is slender thickness, when compared with its height, needed structural support from the house, which it wasn’t getting.

Lateral restraint?

The wall can’t fall inward because it is leaning on (or as we say ‘buttressed by’) the walls, floors, and roof next to it. Outside there is nothing to hold the wall upright. It relies on connections to the house, along all the elements which join it . These were missing. Furthermore, previous alterations had removed some of the masonry bonding, which is crucial in ‘holding’ a gable in place. Developers sometimes put doors in for convenience, without considering follow-on stresses in nearby walls. So here we are. Lateral restraint fixing, whether in new homes, or retro-fitted, connects the outside walls and internal fabric together, so they act as intended, in mutual support. That’s lateral restraint in a nutshell.

Why would a wall, in apparently good condition, just start to move away from the house?

Here’s a little more explanation on the deeper causes of this type of failure. This is a big wall, weighing tons, so surely it could stand up on its own? There are a few reasons why a wall will always tend to be drawn outward if not securely fixed to its neighbour. Mainly, this is wind induced. Though invisible, air is a fluid. When the wind blows walls are subjected to stresses. In effect a wall is pulled and pushed almost all of the time. Air pressure is always moving up or down, that is what wind is. As air rushes from high to low, suction is applied to any wall it blows by. It’s not only gales and storms, even moderate breezes cause a lot of suction on a large surface. This gable is at least 100 square meters in area.

In structural repair language, wind is a dynamic load. Such loads fluctuate, quickly changing from push to pull. The constant buffeting moved this wall, even though it could resist a much greater static load.

The dynamic load moved the wall in increments, sometimes mere tenths of a mm per year, with perhaps faster periods of 1 or 2mm as storms and gales pass by. The important point is that the movement outward was progressive, the wall never moved back. This is because any gaps/cracks are quickly blocked with grit and dust. Only a few grains are enough to resist compressive force that may otherwise push the wall back and close the crack. No, I’m afraid it was a one-way street, with no going back. Filling these cracks without adding ‘lateral restraint’ just helps the movement along.

Other contributary causes can be traffic vibration, poorly managed building work, or nearby foundation work, such as piling. Here’s a link to a case study where a building manager rightly foresaw a need for specialist lateral restraint and wall tying prior to commencing piling work.

Diagnosing the full extent of movement by following the trail up the building

I could see that there were small cracks and gaps here and there, at the spine wall junction with the gable, at the skirting board junctions, joints to some ceiling and walls. Most were quite fine on the face. But the ripples in the wallpaper and evidence of repeat decorating, told me that these were the tip of the iceberg. The cracks beneath were much wider.

As you can see in these images, once I removed some of the ‘rucked’ wallpaper in the joints, and opened cupboards against walls, the extent of movement was discovered. When exposed, some gaps were in the order of 100mm wide. The story unfolded as I followed the trail of evidence and exposed it where needed.

Two types of cracks here – those between the elements, and those caused by failure of over-stressed material.

Lateral restraint is simply the technical term for the bonding at the joint between an external wall and the building. Lateral restraints, like Helifix, and Cintec anchors provide this as a retro-fit where it is absent. But this is only one part of the repair. It’s rare to find no restraint in a building. This was the case here too. There was some good sections of brick-bonding at the spine wall and gable interface. Though because this was compromised by door openings, it was subjected to stress beyond the strength of the base material. As the wall moved, it placed more stress on fewer areas. Therefore the spine wall was cracked in many places, sometimes far back for the junction between the gable and house. These cracks are materials failure cracks. They must be repaired because walls act as a diaphragm, once cracked, even light tensile force will cause them to re-crack. Our client doesn’t need that! For guidance the crack in the previous photo (above) is the former type – caused by elements moving apart due to lack of restraint. – in this case the gable and spine wall. The following image shoes materials failure, where bonding has failed due to the tensile force being too great for the masonry.

Fixing those bulges and cracks

On this project I needed to specify Helifix HeliBars and HeliBond grout to restore the lost structural strength of the cracked walls. Our client needed the door openings to stay (bricking them up was a non-starter). This is where it was useful to encapsulate stainless steel HeliBars in the brickwork, and extend them towards the greater mass of the chimney stack. You’ll see these repairs in some of the images. So we crack stitched to repair continuity AND extended the bars to improve strength, while reducing bearing stress on the base material. This means that the lateral restraint is ‘grabbing more’ and as a result stressing it less. It mobilises much more mass of masonry, anchoring the gable in place.

There’s more to it but not room here, but I have noted one or two interesting tweaks we use to increase the effectiveness of the repair system (see photo captions).

In this case the fabric of the building – it’s spine wall in particular had been torn open by the lateral forces. My job was to identify how we could repair the damage, strengthen the existing bonding, and install addition bonding at as many locations as necessary.

Installing super-strong anchors was the solution of the past. You may have seen large ‘pattress plates’ on old bridges, cotton mills and industrial buildings of the Victorian age? These are unsuitable for most residential and domestic structures. Modern methods seek to reduce stress in the soft lime-based fabric of older houses. We do this by using many fixings, which share the work. Newtons third law of motion states “For every action, there is an equal and opposite reaction”. This is at play in my day to day job because when you anchor something to something the pull of the one thing (gable), is resisted in equal measure by the other (house). Hence, spreading load is always a good idea (can’t argue with Isaac Newton).

In this case a combination of Helifix Helibars and sock anchors were used. Additional strapping was also installed to floors adjacent to the gable, and secured directly to sock anchors in it. These grouted socks extend through the full thickness of the wall, The Helifix HeliBars were integrated into the gable and passed through the spine walls. Cracks in the spine walls were closed for good and the huge gap between the spine and the gable was carefully filled to fully encapsulate and support the HeliBars.

Another completed project with a guaranteed result

Our client is an experienced developer so was able to save expense by completing the internal making-good himself. We did the specialist enabling work we’re famous for.

We received a glowing testimonial. He was delighted by the saving we provided, avoiding a costly rebuild, and surprised how flexible we were at identifying areas he could deliver himself, without impacting on the 10 year guarantee we issued.

The work was complete at the quoted cost, commenced on time, and finished promptly. Our lads enjoyed their Bridlington adventure (especially the fish and chips). Our teams were simultaneously working on structural repairs in Whitby, Leeds and Sheffield, demonstrating what a widespread issue this is. We cover all Yorkshire, and a little further (Teesside, Lincolnshire, Derbyshire and Lancashire too).

Want more details? Try a mooch through our video gallery, it’s full of good stuff on wall tie replacement, lateral restraint and crack stitching.

Our team are the most qualified and expert in this field. If you would like advice on cracks in your building, or one you may be considering buying please contact us. If there is a need for professional work we’ll provide quotations that are fixed (no dodgy estimates), and if you trust us to deliver the project we trust you to pay us for it – there are no ‘up-front’ deposits to worry about.

A ten year guarantee is available and if you are ‘super cautious’ we are always happy to work under your structural engineers supervision (we like that because engineers who watch us work always end up recommending us to others).

Please call us on 0800 591 541 for surveys and advice.