Our team repair thermal cracking for a national media company in Yorkshire

Walls can crack for a wide variety of reasons, ranging from wall tie corrosion, to subsidence, and settlement. But a common reason, particularly of modern buildings is thermal movement. Here’s a recent case where a client’s needed thermal cracks fixed for good.

Thermal induced cracks happen in all kinds of structure. We’ve delivered repairs to hundreds of modern (even brand new) houses, built in the 21st century. Every year we work on large industrial units and warehouses suffering from thermal cracking, wall tie corrosion, or workmanship issues.

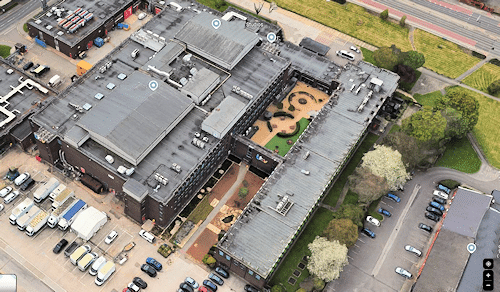

This building is a post war commercial media complex. A sprawling cavity walled structure which has all the built-in ingredients for thermal cracks – lack of movement joints, lightweight masonry, compounded by omissions during construction.

What causes thermal cracking in masonry?

In this building, long stretches of masonry housing large studios multiply the effects of small thermal changes in masonry. But that isn’t all, the use of regular columns of rigid masonry, which embellished parts of the building increase the likelihood of cracking. Whilst columns can strengthen masonry, poor design can result in excessive rigidity. These points of restraint (stopping thermal movement by force), merely enhance long-term cyclical cracking.

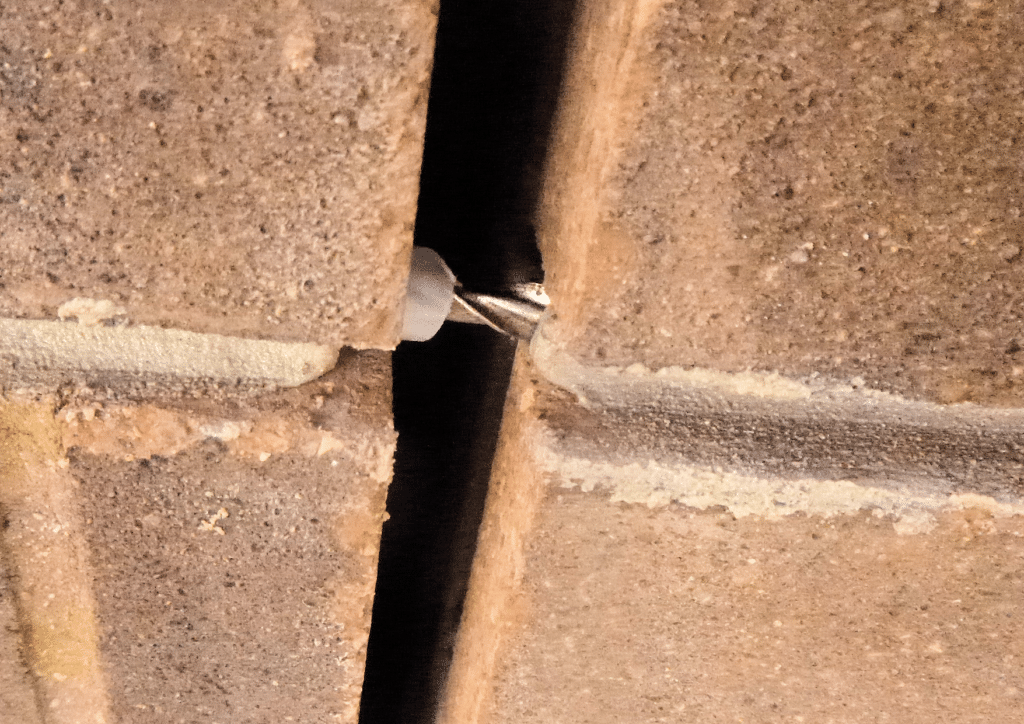

What happens is the masonry readily absorbs the expansion, because it is very strong in compression. However, as the expansion relaxes, that compression is replaced by tension. Tension is the mortal enemy of masonry. The poor tensile strength of brick and mortar is exposed in very characteristic crack patterns. Tending to happen at or near points of restraint, and areas of brickwork with the weakest tensile strength. These include those that are narrow in height, in relation to horizontal span. Under windows, at heads of walls and next to restraining columns – as on this large building.

A targeted approach to thermal cracking – our specification for repair

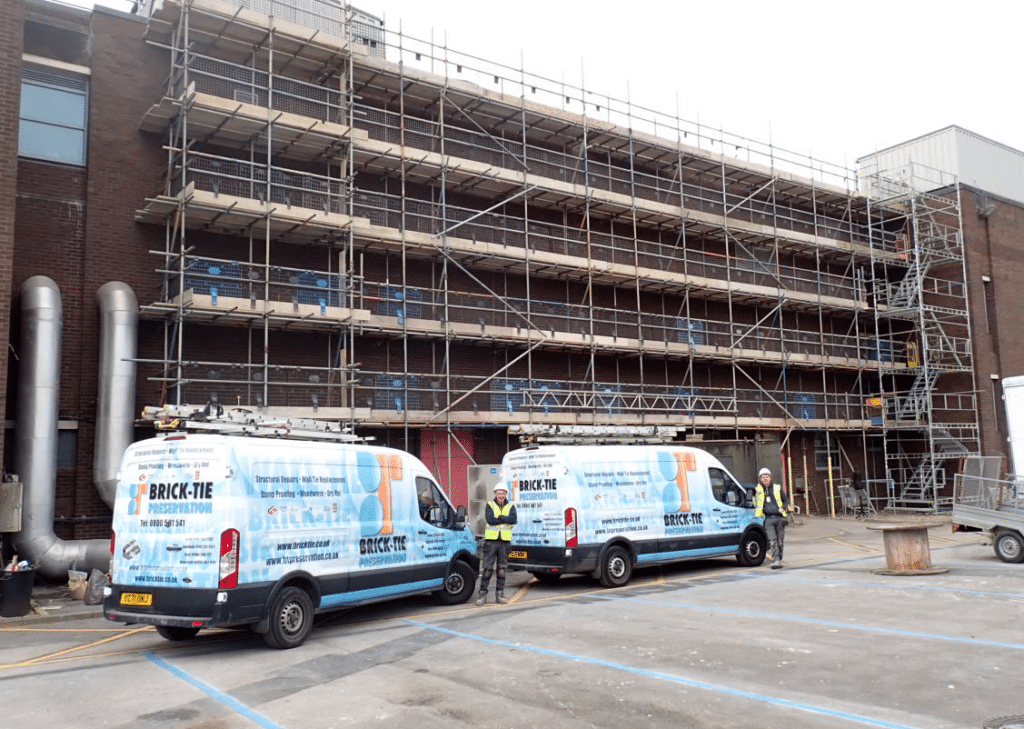

Our survey team were asked to help via our clients structural engineers. They made an initial diagnosis and asked us to help. Our reputation for practical and innovative problem solving was already known. But in this case our Helifix Approved installer Accreditation also factored. A long-term guaranteed solution was essential for our client.

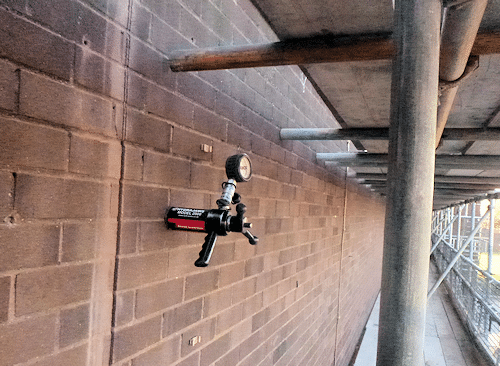

A broad range of interventions were agreed, which included over ten full height retro-fit movement joints around the area. Precision cut by our own skilled team of technicians, the joints accommodate the cyclical movement of the masonry as it warms and cools throughout the year. Helifix remedial wall ties were needed because whilst the joints were essential, cutting walls into vertical slices disrupts the flexural strength of masonry. Without these remedial ties, the newly formed independent cladding sections would be at risk of failure, due to wind loading. Hundreds of Helifx ResiTies, and Slip-Ties were needed, to counter this. Our remedial wall tie technicians are the most qualified and experienced in the industry.

This work was completed over several weeks in the summer. The studios are home to a media company, of national importance, shooting news, drama and the whole gamut of TV content, we were tasked with working in a carefully structured way, quiet efficiency, and sensible planning sorted that.

Yorkshires top wall tie and crack repair team – our service to you

Feedback from the independent structural engineers, client, and their ever-present security team was excellent. For security reasons we cannot name them, but we thank them all.

The key requirements requested by our client were:

- Correct diagnosis and investigation, to identify the reason for the cracks – done!

- Identifying the most cost-effective and practical way of repairing the issue, and protecting the building for the future – done!

- Delivering work in the most unobtrusive and sympathetic way possible, to the highest standards, and

- testing the work along the way, to making sure the client received a worthwhile guarantee – DONE!

Brick-Tie was established in 1986 and it is the premier name in Yorkshire for structural masonry repairs and wall tie replacement work. Commercial, listed, historic, and residential property are included.

Wall tie installations, movement joints, lateral restraints, HeliBeams, specialist stitching anchors and repairing all types of cracks in buildings are our specialty.

Call us or email via our contact page. You can also call us on tel:0800591541 we cover all Yorkshire and a little further too. We work on buildings of any age and size. Small terraced homes and multi-story blocks included! Want thermal cracking fixed for good ? Brick-Tie are Yorkshires best and longest established Helifix Approved Installers.